The Science Behind Perfect Record Attempts

At Gourmet World Records, every certification is built on evidence, precision, and transparency. Behind each record attempt lies a rigorous scientific framework designed to remove ambiguity and ensure that results are accurate, repeatable, and independently verifiable.

Dr. Aisha Kaur, Technical Director at Gourmet World Records, leads the development and oversight of these protocols. With a background spanning food science, applied measurement systems, and audit methodology, her role is to ensure that every record we certify can withstand professional, legal, and industry scrutiny.

Measurement Before Spectacle

“Scale and creativity may draw attention,” Dr. Kaur explains, “but records are validated long before the first product is laid out.”

Each attempt begins with a pre-certification technical review, during which the proposed record is defined in measurable, objective terms. This includes:

- Exact definitions of what is being measured

- Inclusion and exclusion criteria

- Environmental constraints (temperature, time, handling conditions)

- Acceptable tolerances and margins of error

This phase ensures that records are comparable over time and that results cannot be inflated through interpretation or presentation.

Calibrated Tools, Controlled Conditions

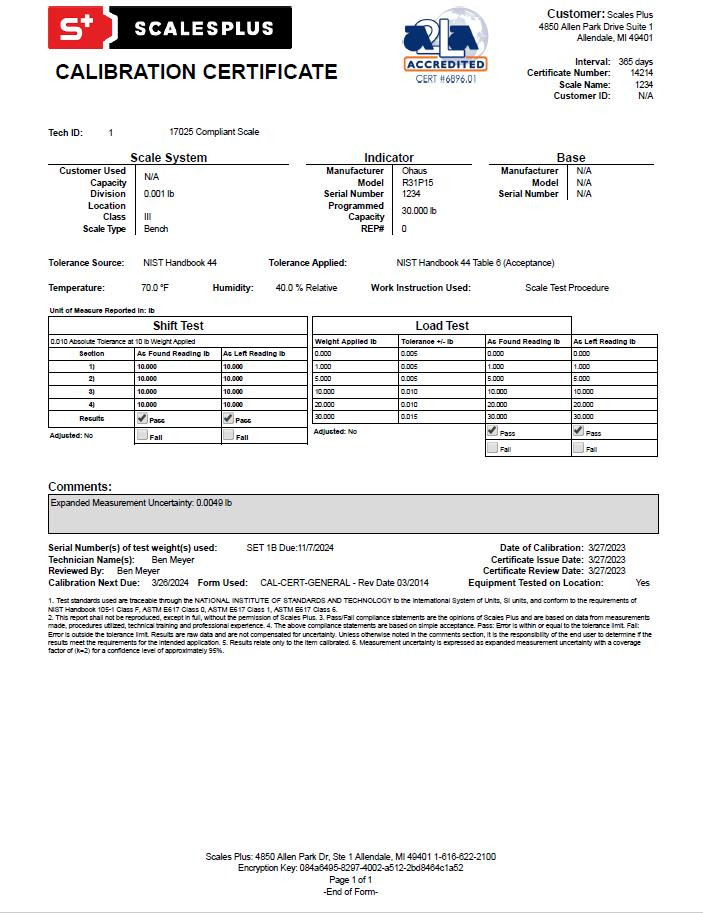

All measurements conducted during a Gourmet World Records attempt rely on calibrated, traceable instruments. Scales, volumetric tools, and timing devices are verified against international calibration standards prior to use.

4

Environmental factors such as surface stability, airflow, humidity, and product temperature are also controlled or documented, ensuring that results reflect real, reproducible values rather than idealized conditions.

Independent Verification

No record is certified based on internal observation alone. Each attempt is monitored by on-site officials and supported by independent third-party auditors, who review methodology, raw data, calibration logs, and photographic and video evidence.

“All data must tell the same story,” Dr. Kaur notes. “If the measurements, documentation, and visual records don’t align perfectly, the certification doesn’t proceed.”

This layered verification model eliminates conflicts of interest and reinforces the credibility of each record.

Documentation as Proof

Every Gourmet World Records certification is accompanied by a complete technical dossier, including:

- Measurement logs and timestamps

- Calibration certificates

- Process photography and continuous video capture

- Auditor sign-off and technical summaries

This documentation is archived and remains accessible for future reference, comparison, or revalidation.

Precision That Protects Credibility

In the food and beverage world—where craftsmanship, sourcing, and scale are constantly evolving—records must be more than impressive. They must be defensible.

“Our responsibility,” Dr. Kaur concludes, “is to protect the integrity of the record itself. Precision is not a formality—it is the foundation of trust.”

Through science-led protocols and uncompromising verification standards, Gourmet World Records ensures that every title awarded reflects not just ambition, but measurable, proven achievement.